Home / Products

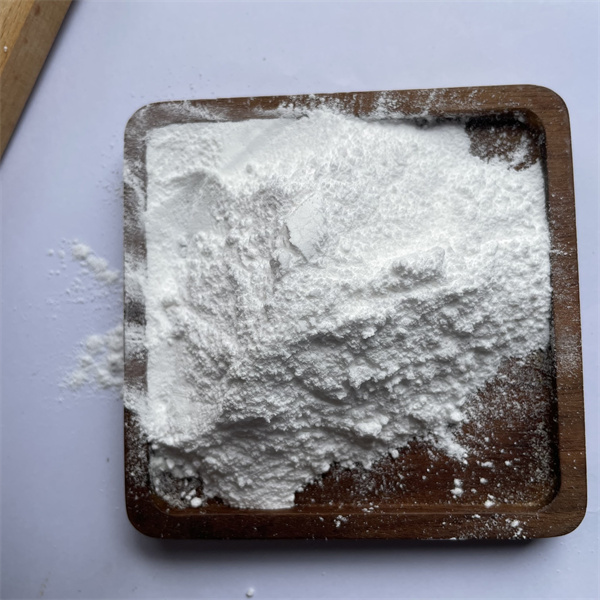

Polyvinylpyrrolidone (PVP) is a versatile synthetic water-soluble polymer known by its CAS number 9003-39-8. PVP is widely used in pharmaceuticals, cosmetics, food additives, and other industries. With advancements in medical technology, its applications in the pharmaceutical sector have expanded significantly, particularly as a drug carrier and hemostatic agent. Beyond pharmaceuticals, PVP is utilized in electronic chemicals, coatings, adhesives, and more. The global demand for PVP is steadily growing, with Asia leading the market due to its large population and rapid economic development.

Basic Information

PVP exists in several forms, distinguished by their K-values, which relate to the polymer’s average molecular weight and viscosity. PVP K-30 is a non-ionic, high-molecular-weight compound, known for its adhesive properties, water solubility, and hygroscopic nature. It can be plasticized with water and organic plasticizers, forming clear, hard, glossy films. PVP K-90, on the other hand, is renowned for its excellent biological stability and chemical inertness, making it ideal for applications in cosmetics, tissue engineering, and biomedical engineering.

PS Chemical Consortium is a leader in the production of high-quality PVP, leveraging state-of-the-art manufacturing processes. The company, established through the cooperation of seven large chemical enterprises, operates across several locations, including Weifang, Shandong, and Ezhou, Hubei. Covering over 80,000 square meters, our facilities house more than 200 experts in biological and chemical sciences.

Our production process begins with the procurement of raw material BDO, which is processed into gamma-butyrolactone (GBL), then into alpha-pyrrolidone (α-P), and subsequently N-vinylpyrrolidone (NVP). Through polymerization, these intermediates are transformed into various grades of PVP products. We utilize advanced solution polymerization techniques, ensuring our PVP products' high purity and consistent quality. Our current annual production capacity stands at over 20,000 tons of PVP, with plans to expand based on market demand.

High purity. Our products meet stringent USP standards.

High purity. Our products meet stringent USP standards. Good supplier. We adhere to strict environmental regulations, implementing green and sustainable production processes.

Good supplier. We adhere to strict environmental regulations, implementing green and sustainable production processes. Professional factory. We can meet large-scale demand and ensure timely delivery of high-quality PVP products.

Professional factory. We can meet large-scale demand and ensure timely delivery of high-quality PVP products.